News & Stories from Romtec Utilities

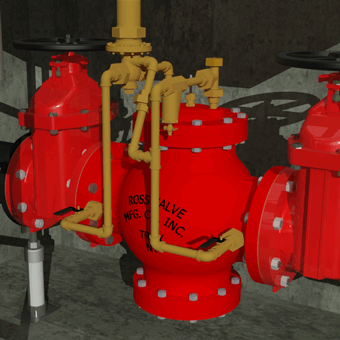

Romtec Utilities designs, engineers, manufactures, and supplies complete pumping systems for a wide range of applications. In addition to our full systems, Romtec Utilities also offers auxiliary systems that can be engineered and prefabricated for site-specific projects. We are now offering a new prefabricated product with complete pressure relief and pressure reducing vaults and assemblies, also called PRVs for short. In a pressure system for sewer or water mains, there can be many reasons for

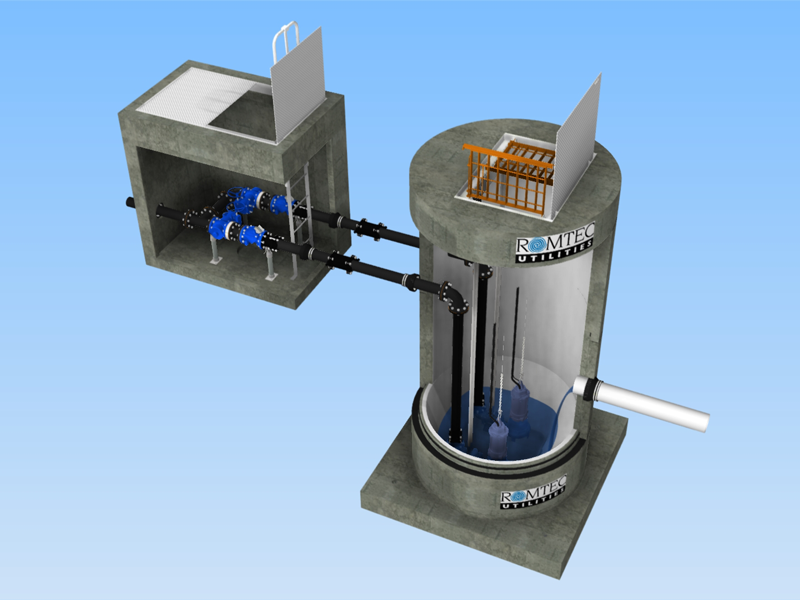

Romtec Utilities engineers and supplies complete pump stations with all structural, mechanical, electrical, and communications systems, and the overwhelming majority of new pump stations utilize submersible pumps. Pump maintenance is an ongoing and important facet of owning and operating a pump station. This means that at some point it is likely the pump will have to be lifted from the wet well for maintenance. Although this is a common activity that occurs regularly in most

Romtec Utilities designs every aspect of new pumping system, including all of the structural, mechanical, and electrical systems. Communication devices, primarily called telemetry, are also included in our design and engineering services. Communication to and from a pumping system can dramatically affect the long-term operational success of a system, and there is no right or wrong type of telemetry to use. Choosing the best telemetry involves understanding the culture of your organization and finding a

Romtec Utilities designs, engineers, manufactures, and supplies all types of pumping systems for a wide variety of applications. The duplex pump configuration is one of the most common configurations in a pump station design, and it provides owners with several benefits. A duplex configuration means that there are two pumps in the system. Pump stations can also be designed as simplex, triplex, and up to pentaplex configurations, all depending on how many pumps are required

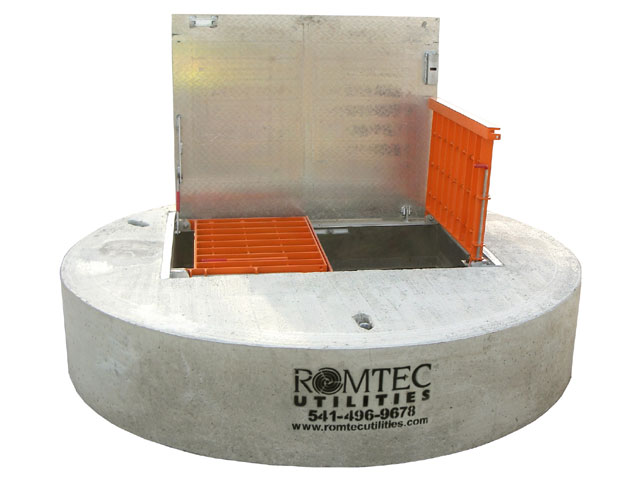

Romtec Utilities engineers complete pumping systems, and the structural components are one of the major assemblies for our systems. On virtually every project, the structural assembly carries a load rating specific to the weight tolerance of the system’s structural components. These ratings apply to the well structures, vault structures, and any access hatches. Hatches, in turn, must be designed in such a way to remain functional and easy to use as well as to meet