Pump stations are the combination of many individual components working together to convey liquid from one location to another. Level sensors are one set of components that are integral to the operation of a pump station. When pumps are triggered and when they shut off are both governed by liquid measurements collected from level sensors. This is a continuation for the multi-part blog series covering each of the level sensor technologies Romtec Utilities commonly uses in pump stations. Today we’ll be covering ultrasonic transducers, a reliable level sensing method that uses acoustic signals to determine levels inside the wet well.

Ultrasonic transducers are a powerful measurement tool that extends well beyond the pump industry, from medical applications to automatic industrial processes. These sensors can accurately measure a tanks contents in many different conditions. Like their name suggests, ultrasonic transducers use acoustic signals to measure levels. These signals reflect off of the surface of the material and are measured by timing the delay between when the signal was sent and received. This action is performed multiple times and then averaged for an accurate measurement. However, turbulent conditions inside the wet well or the presence of sound absorbing materials, like foam or even spider webs, can skew these measurements. Here are two projects where ultrasonic transducers were chosen to provide reliable level sensing.

Orange County Groundwater Replenishment System

A large groundwater replenishment system in California required a high flow pump station to distribute “clean” stormwater across a large recharge basin. This is a large pump station that handles over 3 million gallons of stormwater daily with a duplex configuration of turbine pumps. Additionally, a large 20’ deep wet well was used for the wet well to provide enough temporary storage between pumping cycles. Romtec Utilities selected an ultrasonic transducer for primary level sensing in this stormwater application for its long term reliability and accurate measurements.

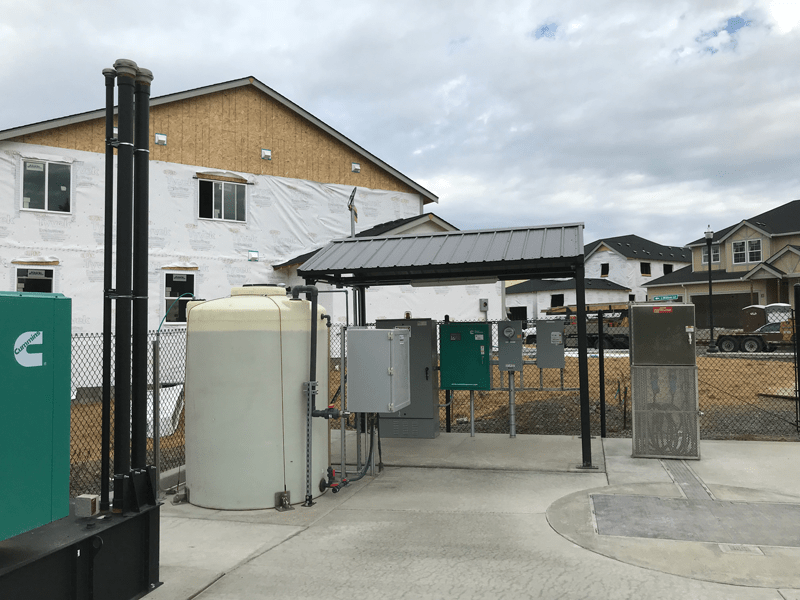

Kennedy Farm

Romtec Utilities was hired to design, supply, and manufacture a new wastewater lift station for a residential development in Ridgefield, Washington. This is a typical lift station that will collect wastewater from the newly constructed homes using 11hp Flygt pumps. Once again an ultrasonic transducer were chosen as the primary level sensor, but turbulent conditions caused by cascading inflows presented a design challenge. Romtec Utilities included a drop bowl assembly at the inlet to mitigate these concerns. Combining components in this fashion is one of the most effective ways to create favorable environments for a pump stations operation.

Level sensors are an important component in every pump station, and Romtec Utilities will include any brand or style of sensor to meet your projects requirements. Ultrasonic transducers provide accurate level measurements of many materials and operating conditions. Combining these powerful level sensors with other components, like drop bowl assemblies, deflector panels, and in-well mixers, can greatly improve their accuracy under challenging operating conditions. Contact Romtec Utilities for more information about ultrasonic transducers and other level sensors today!