Prefabricated package pumping systems are assembled to the highest degree possible before we send them to a job site, cutting down on installation costs, time, and equipment needed to install.

We go through a prefabrication process that includes pump station assemblies, valve assemblies, vault assemblies, along with control panel testing, all of which cut down on construction time, costs, and the equipment needed for installation. We take these steps to ensure the system operates as it was designed; while also providing a high level of quality control making sure the system works and is tested for operations.

At Romtec Utilities we design, manufacture, and supply complete package pumping systems to our clients in a variety of developments and water types. We work with the owners to meet their pumping needs while partnering with the various contractors involved in the project, to bring it to life. We can prefabricate a wastewater pump system, on a fast timeline to ensure the installation is done quickly to a keep a project moving forward.

Romtec Utilities Pump Station Prefabrication Process

What Does Romtec Utilities Prefabricate?

At Romtec Utilities, we go through a strenuous process to prefabricate package pumping systems.

Romtec Utilities prefabricates all necessary components of the pumping systems we design and supply for our customers. Our pump stations come with a high level of prefabrication due to the unique nature of every project that we create in partnership with the owners, project engineers, and other vendors.

Each system is designed based on the specifications and requirements associated with the project. In most pump station projects, the system will be too large to prefabricate the entire pump station and then ship it to the job site. Therefore, we prefabricate the parts that can be prefabricated and delivered safely to the site.

Prefabricated pump stations are a great advantage for owners and contractors as they reduce installation time and equipment requirements. Our team prefabricates pumping systems to ensure a high-quality system will be installed as it was designed.

Prefabricated Pump Station Assemblies

Packaged pump stations typically contain several large assemblies. There is a pump assembly, the valve assembly, the control panel, and many other potential auxiliary assemblies.

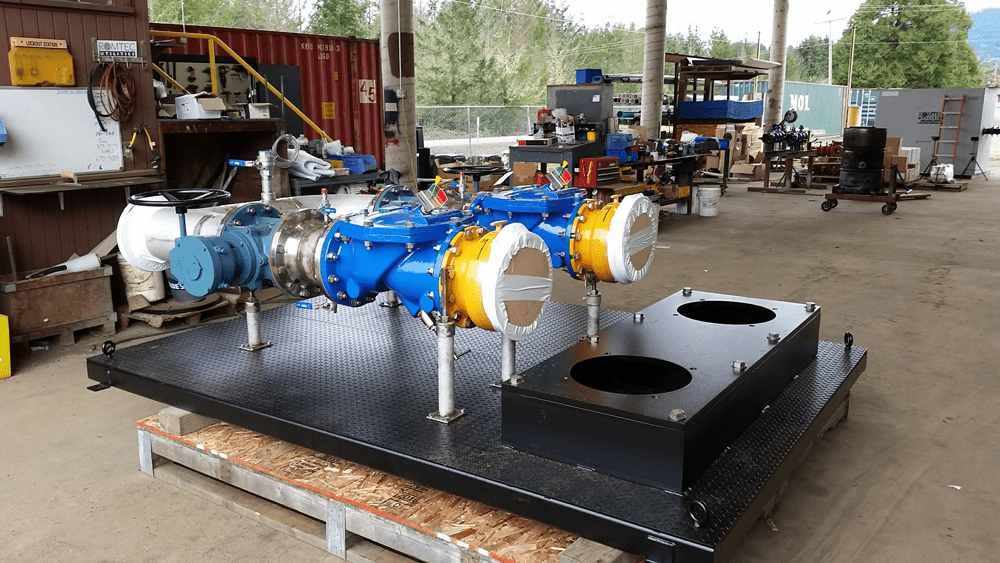

Complete Valve Assemblies

Romtec Utilities designs, manufactures, and supplies complete valve assemblies that can be installed above grade or below grade in a prefabricated concrete vault. The valve assemblies are designed for specific water conditions like wastewater or stormwater and pumping requirements like flow, dynamic-head, and force main pressure.

The valve assemblies are delivered prefabricated, and pressure tested for leaks with every component completely installed. Basically, you’re getting a finished unit that is ready for installation and guaranteed to hold pressure once connected to your pumping system.

As Romtec Utilities does the engineering of the valve assembly, we also house the complete assembly in a valve vault that is made of steel, fiberglass, or precast concrete.

Instituting the design features, you want in a space that you can work in is something that Romtec Utilities does for each valve assembly we deliver.

If there are specific components or special needs, we can accommodate those things into the design and fabrication of a reliable valve assembly for our prefabricated package pumping systems. We work with all manufacturers and materials to ensure that the customer gets exactly the components they need.

Auxiliary Vault Structure

Vault assemblies are composed of valves, meters, air release valves, pressure relief valves, pumping ports, pigging ports, and other components. Creating a good vault structure for your auxiliary system is vital to a good pump station.

Having an auxiliary vault that is separate and safer to access than the well structure benefits personnel. Romtec Utilities specializes in providing accessibility to these components for maintenance while thinking about the space and overall design of the vault.

Romtec Utilities prefabricates the vault along with installing all the vault assemblies ensuring the system is set up for success as it arrives for installation.

Muffin Monsters Prefabricated Mold

Typically, Muffin Monsters in the gravity flow line require a specific channel mold that must be poured on site. For specific projects, such as the PDX TCORE project, Romtec Utilities explores ways to save time in construction by prefabricating this component. Custom, prefabricated basins allow for an easy, fast installation, and a smaller footprint than traditional installation methods.

Romtec Utilities’ engineers were able to design a prefabricated mold that places the muffin monster into a manhole. Inside the channel, the Muffin Monster sits on guide rails to allow for easy lifting of the Muffin Monster for maintenance and access. This pre-cast method for the Muffin Monsters allows Romtec to perform all pre-work and quality control checks prior to arriving on site.

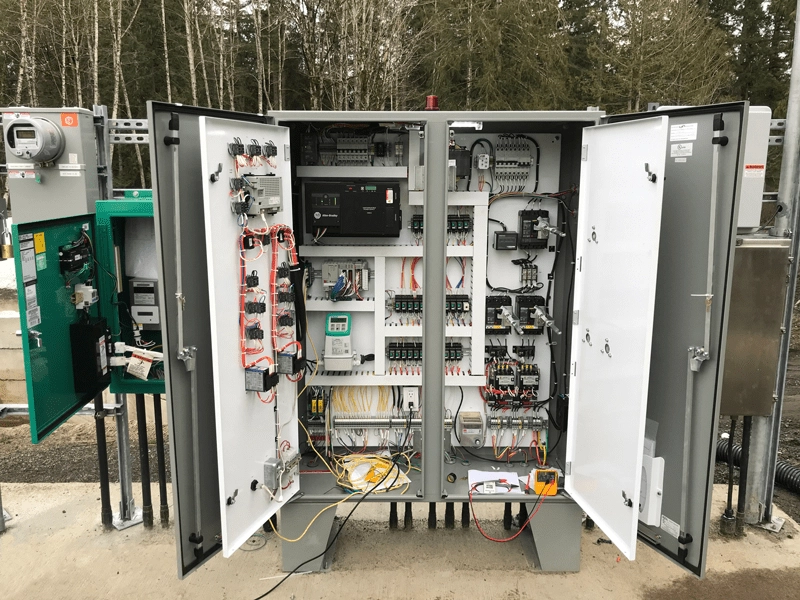

Control Panels

Romtec designs and prefabricates all aspects of the control panel for a pumping system. The control panel can be simple as alternating relays and as complex as industrial-grade program logic controllers (PLC’s) with color human-machine interfaces (HMI’s). We design the control panel to fit your maintenance and notification requirements.

Romtec also tests the control panel system to ensure its proper operation before it is sent to the project site for installation.

Prefabrication Saves Time at Install

The key to good, prefabricated package pumping systems is to understand each assembly, how it all works together, and how it will be installed onsite.

With this level of expertise and understanding, Romtec Utilities can specify in detail the complete scope of the prefabrication work as well as the scope of the work that will need to be completed at the time of installation. This is how prefabrication saves costs upon installation of pump system, as we understand the entire process including installation.

Central Point III, Caprock Project

For this logistics facility, in Visalia, California we designed a wastewater lift station for the campus that will include several buildings in future years. We worked with the developers before on similar type projects for logistic buildings, so we had an established working relationship with them. Having this relationship was helpful in conversations about our prefabrication and how it can help with the installation process which they were able to take advantage of. Another advantage of this is limiting the damage or excavation to the site.

That is why Romtec Utilities prefabricates package pumping systems.

Prefabrication Takes the “Guess-Work” Out of Installation

When it comes to Romtec Utilities prefabrication and the benefits relative to installation, there are many. Saving on time, work, disruption to the site, and equipment needed are some of the main benefits.

Prefabricated package pumping systems allow for minimal or no work to have to be performed “in the hole” and they allow for a more precise installation. With a prefabricated lift station, excavation can be minimal, reducing the impact to the site.

On Romtec Utilities projects, because of the prefabrication aspects, we can provide refined pick weights for each structural piece. We know the weights, sizes, and scope of remaining work needed to be done on-site. This allows the contractor to preemptively select the best equipment for installation.

In the case of Caprock Point, a gradall telehandler, front end loader, and crane were all used. The gradall and front-end loader are transporting the equipment around the site. The crane was used to set the equipment in the hole. Depending on the depth of the system though, all the equipment could potentially set the wet well.

Another unique aspect of the installation of the Caprock Point project is that they used a large auger to drill the hole. This is a less common method, but it really keeps the on-site excavation to a minimum.

This is a great example of how minimally invasive the installation could be (especially in dryer conditions).

The prefabrication of our systems helps save time, money, the equipment needed upon installation, and disruption to the site depending on the project.

When you prefabricate package pumping systems, it helps in a variety of ways including the final product and installation process which has a variety of benefits to the customer.

Comments 2

Working on design for an industrial clients with multiple sumps. What is the largest precast sump you could ship. We would be looking for the pumps and controls as well.

Author

Dave,

Thank you for your inquiry. A Romtec Utilities Representative will be in touch with you soon.

Sincerely,

Romtec