Many owners or entities who maintain a pump system opt for controls that are outside of the capabilities of their field service staff. This can be an issue when maintenance problems arise or alarms on the system alert those who maintain it.

Staff may not know how the whole system works, or how to get the system back to operating normally with the controls or sensors they have in place.

That is why understanding what your facility needs and how it operates is critical to making pumping system decisions that work for your application.

The smart controls design depends on the technical know-how and capability of the operation and maintenance staff.

Selecting the tier of controls that best fits your staff’s capabilities is an important part of designing the controls on a pump station.

Owners Preference & Application

The standards and requirements set forth by the end owner will typically express their likes and dislikes. Some common items that owners will have preferences on are the system controller, level sensing and pumps.

The end owner determines how complex a system needs to be along with the staff who maintain it.

In some cases, an owner has property management companies and operations and maintenance personnel who have never seen or operated a pump station.

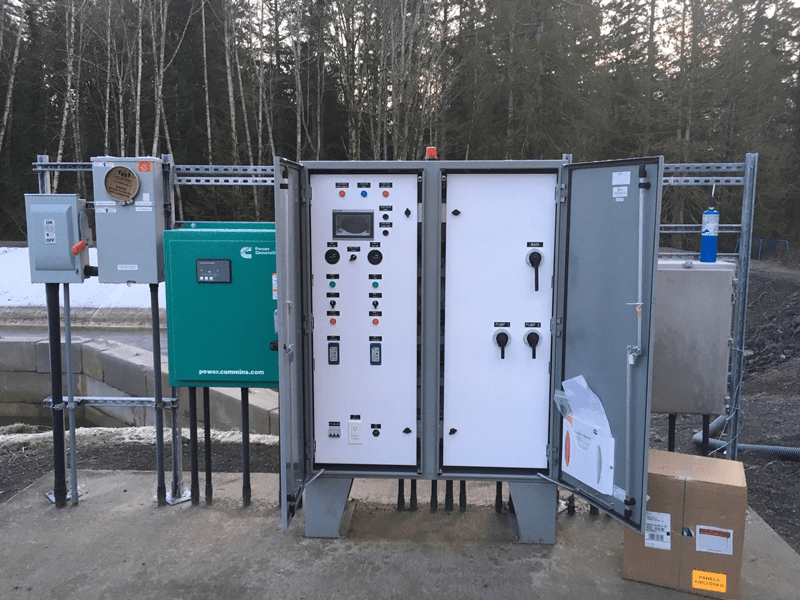

These owners should look for a simplistic design as it will be most useful for maintaining the pump station long-term instead of a more complicated system.

These individually owned and operated pump stations may not have a designated staff or team that maintains the system daily. These types of owners have homeowners’ associations, landscapers, or home and commercial property maintenance staff to do the job. To these owners, the pumping system is unfamiliar and while they must have it, they only have one or two pump systems compared to a big stormwater district.

These types of owners want simplicity with easy-to-understand controls and operating procedures. They also want less information and fewer alarms. They simply want absolute reliability out of the system.

They also want on-site control and information only with the ability to start and stop the system. Additionally, they prefer to get a notification if there is a problem and to have a local pump service company they can call.

This type of owner does not want (or have the know-how) to deal with an alarm. This type of entity needs a pump station service company to handle all alarms and the operation and maintenance of their pump station.

With all the variables these items provide, it can create more data and alarms to monitor the system but again that depends on the knowledge and preferences of the maintenance staff.

Sanitary Sewer District Owners with Significant Collection Systems

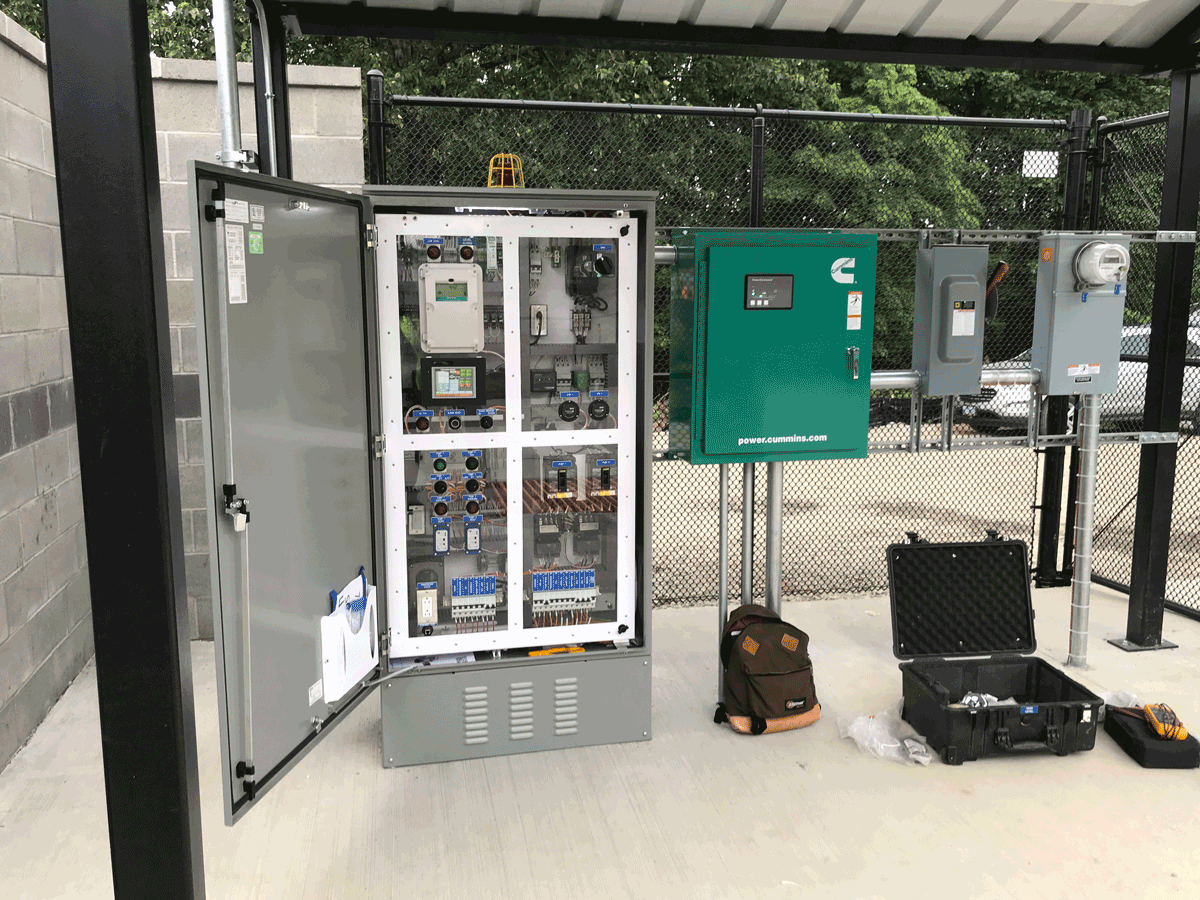

In some situations, an owner has several pumping systems and adequate personnel who can handle all the latest pumping control and communication schemes. A sanitary sewer district with significant collections systems may control dozens of lift stations within their system. They have back-up start and stop controls, backup pumps, backup power and backup operational control configurations.

This type of owner could want certain features or controls that improve the life span and reliability of each pump station.

This is where a more complicated system makes sense.

These owners often have 24/7 treatment plants with experienced full-time personnel monitoring all lift stations in the overall collection system.

These types of owners care about standardization of the pump system via parts, layout, and operating methodology. The cost of the system and its longevity of it are also important. Being able to ‘control all’ of the operation at the site location or the command center.

This type of owner can truly benefit from sophisticated control schemes based on PLCs (programmable logic controllers) and HMIs (human-machine interface) and/or highly sophisticated proprietary controllers.

What Matters Most

Except for the most complex water and sewer districts, a pump station’s sophistication is not as important as the station’s reliability. If reliability is defined by the frequency a station produces alarms, then a station with the fewest alarms is best.

The more sophistication, the more alarms that will likely occur because there are more things to monitor.

That’s why we suggest being realistic when it comes to evaluating your operation and maintenance staff’s ability to respond 24/7.

It’s important to design and build reliability in a way that fits the crew and what they understand, not in the form that fits what someone thinks the crew should be able to understand.