Naval Base Kitsap – Multiple Lift Stations for a High Security Base

Project Description

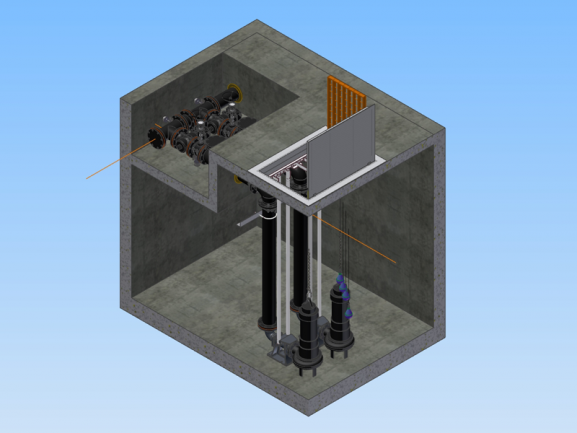

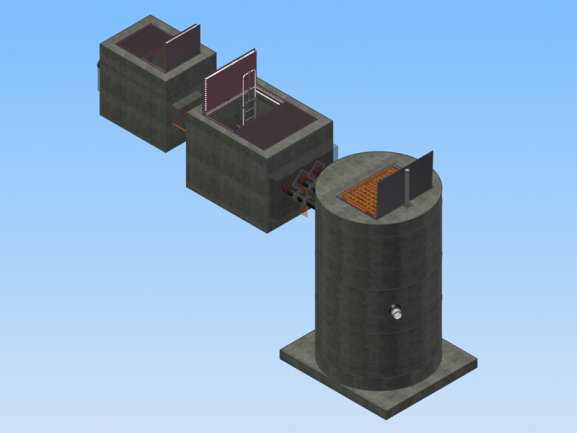

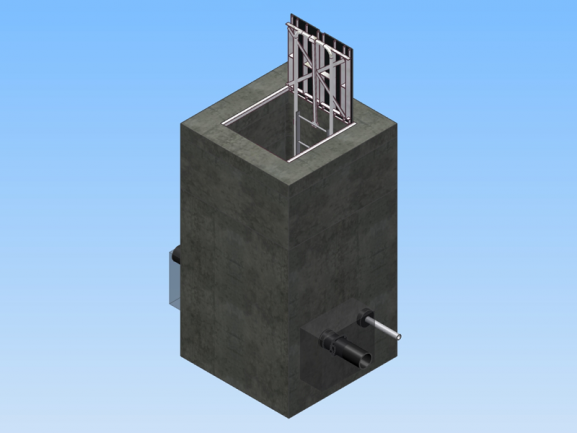

Romtec Utilities designed, engineered, and manufactured five unique lift stations for the Naval Base Kitsap in Washington. Four of the lift stations were new systems, and the fifth was a retrofit of an existing wastewater lift station. The most powerful of these lift stations is engineered with 50 hp Ebara submersible pumps in a triplex configuration and pumps over 1,100 gallons per minute. Although the flows of each system vary greatly, they share many of the same design elements, like the use of ultrasonic transducers and Unitronics electrical controls. All of these systems use below-grade vaults to house their valve assemblies while providing easy access for maintenance. Getting all five systems through Romtec Utilities allowed the Base to get unique systems that are similar to operate and maintain.

What Romtec Utilities Provided

- Lift Station Design & Engineering

- Package Lift Station Supplier

- Package Lift Station Manufacturer

- On-Site Lift Station Construction Adviser

- On-Site Start-Up Management

| 100-1,160 | 40′-130′ |

| GPM | TDH |

Why They Chose Romtec Utilities

Romtec Utilities was first contacted by WHH Nisqually, the contractor, to provide the design and supply of five total lift stations for this nuclear submarine base. We worked with the project’s engineer, Parametrix, on the initial designs of the lift stations, which are spread throughout the large Naval Base. This was an important project, and it was subject to many rules and regulations, including a USA-Only manufacturer’s requirement. Romtec Utilities was selected for this project because of our ability to provide both the design and supply of all the lift stations per the Navy specification. Working with an experienced pump station engineering firm like Romtec Utilities helped the Navy on this project because of the tight security requirements and Romtec Utilities’ ability to work in highly secure and difficult locations.