Romtec Utilities designs and supplies pumping stations for a wide variety of applications and water types. We have designed for nearly every scenario, including systems that need to achieve multiple different pumping rates. There are a couple of ways to achieve multiple discharge rates, and the best way for a system may be simpler than you think.

In stormwater, wastewater, and industrial pumping applications there are a variety of scenarios in which minimum or maximum discharge rates need to be met. The discharge rate is the amount of water that can be pumped out of a system, often measured in gallons per minute. These rates are often determined by “where” the water is going, “what” is on the receiving end, and even the size of the force main. Depending on the conditions and local building codes, a pumping system may need to be able to achieve multiple different discharge rates to adequately meet demand. For instance, in stormwater pumping applications, the system often has to meet a discharge rate for daily flows as well as larger 100 or 150 year storm events.

One method for achieving multiple pumping discharge rates is through the use of VFD’s, or Variable Frequency Drives, which “control the frequency of the electrical power supplied to the [pump] motors” (“Variable frequency drive”, n.d.). VFDs are needed if the operator of the lift station needs to change the performance of the pumps at lower or higher frequencies. By changing the power output to the pumps, the VFD can alter the discharge rate of the system.

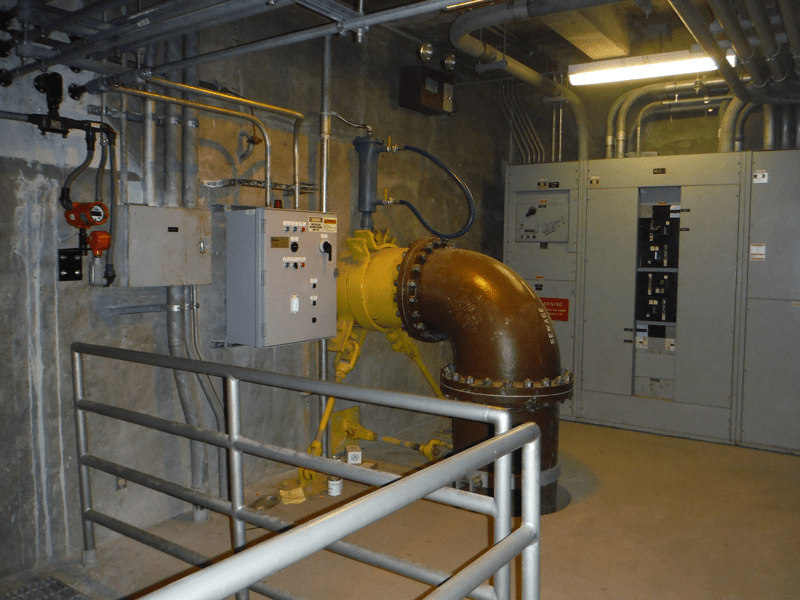

VFDs are needed if the system needs to truly run at variable frequencies and are commonly used in scenarios that involve many or very specific discharge rates. While flexible in their ability, VFDs can also be complex and expensive additions to a system. VFD panels can become very expensive, and then often require the addition of a PLC, or programmable logic controller, that will control the pumps.

A common misunderstanding is that VFDs are the best way to achieve multiple discharge rates because the operator can just turn the pump down or up to achieve the pumping rate they desire. But there are other ways to achieve multiple pumping rates that can save time and money. While VFDs are impressive pieces of technology, the addition of a VFD can add a lot of money and interface complexity that simply may not be needed.

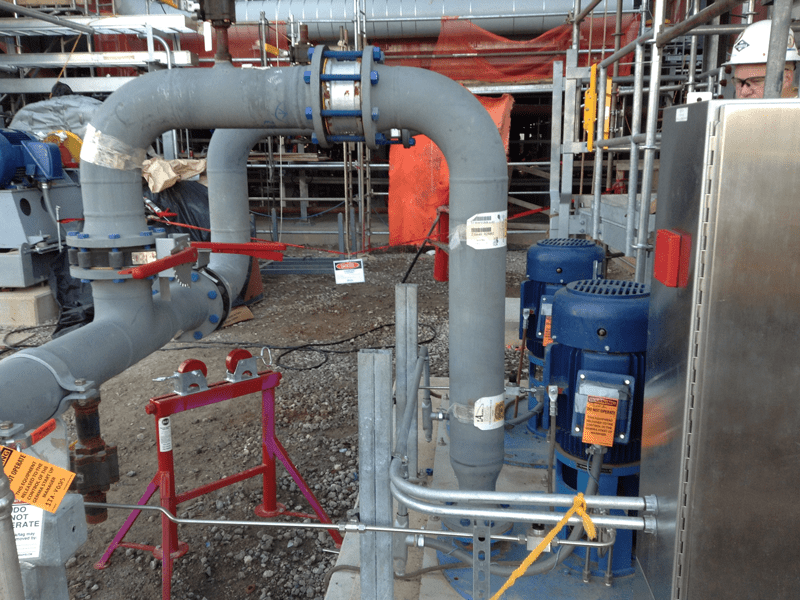

In many cases, it is less expensive and more reliable to achieve multiple discharge rates with multiple pumps than with complex technology. This approach is often misunderstood but is a simple approach that allows a handful of different discharge rates to be achieved. The pumps in these systems may be the same size, or each may be a different size to achieve a variety of pumping rates. For example, in a system with two pumps, one pump may be smaller to achieve a lower rate, the other pump may be larger to achieve a higher rate, and the two pumps combined could achieve a third discharge rate for the system. Start and stop of the system would be based on water level or which pumping rate is desired. For lower flows, the smaller of the pumps would kick on, and the larger pump would engage during higher flows when the water inflow exceeds the discharge rate of the smaller pump.

The multiple pump method to achieve multiple discharge rates has a couple of benefits. The first is pump redundancy; if one pump fails, the other pump, or pumps, would still be able to engage to discharge water from the lift station. In wastewater situations, pump redundancy can prevent disastrous overflows and expensive clean ups of hazardous wastewater. Another benefit is that this method does not require any special or complex technology to work, potentially making it easier for maintenance personnel to operate, maintain, and troubleshoot the lift station without working with complex technological components. Overall, using multiple pumps to achieve different pumping rates can be a more reliable method in situations that do not necessitate a VFD.

There are many reasons that a system may need to operate at multiple pumping discharge rates in stormwater, wastewater, and industrial applications. For projects and situations that must meet required or mandated pumping rates, it is best to try to do it in the simplest and most reliable way first with the multiple pump method. Only when that is not a possibility should you investigate VFDs for your system. Having installed pumping systems across our nation, Romtec Utilities has designed for nearly every possibility and our experts have the knowledge and experience to determine the best option to meet our customers’ pump station discharge needs.

Variable frequency drive. Grundfos.com. Retrieved 20 March 2022, from https://www.grundfos.com/solutions/learn/research-and-insights/variable-frequency-drive

Comments 1

Thank you for very useful explanation of options regardin multiple discharge rates. I always learn something new reading your articles.