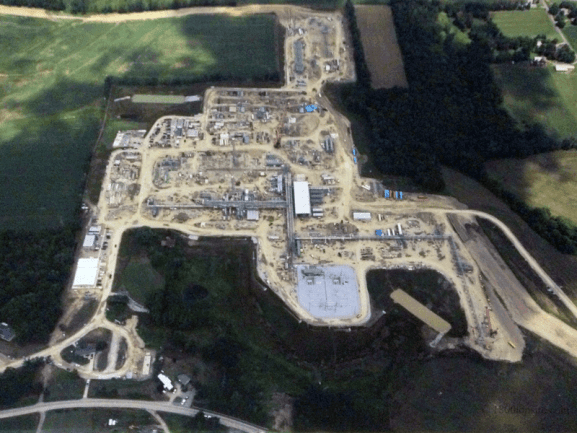

Utica East Ohio Midstream LNG Plant – Double-Wall Fiberglass Sumps

Project Description

Utica East Ohio Midstream needed two new pump stations to handle low flows of stormwater runoff at its new Kensington Plant in Ohio. To responsibly contain potentially hazardous stormwater from the topsoil, these pump stations were designed with double-wall fiberglass wet wells with interstitial leak detection. Both pumping systems included corrosion resistant components and sensors due to the potential presences of LNGs in the stormwater runoff. Pumps were engineered with 7.5 hp Ebara pumps in a duplex configuration, and different impellers were specified for each of the two pump stations meet slightly differing head requirements.

What Romtec Utilities Provided

- Lift Station Design & Engineering

- Package Lift Station Supplier

- Package Lift Station Manufacturer

- On-Site Lift Station Construction Adviser

- On-Site Start-Up Management

| 75 | 67′ |

| GPM | TDH |

Why They Chose Romtec Utilities

URS Corporation, the project engineer, contacted Romtec Utilities for the design of three pump stations, including these two pump stations with nearly identical designs. URS provided Romtec Utilities with the design criteria and requirements for double-wall fiberglass wet wells, corrosion resistant components, and value engineering services. Romtec Utilities worked to design these pump stations to meet the URS requirements while satisfying the budget of Utica East Ohio Midstream, the end owner and customer. When the designs were completed, Romtec Utilities manufactured the pump station packages and delivered them to the plant construction site in Ohio where Fagen, Inc. installed all three pump stations.