Dow Chemical Company – Replacement Fiberglass Lift Station

Project Description

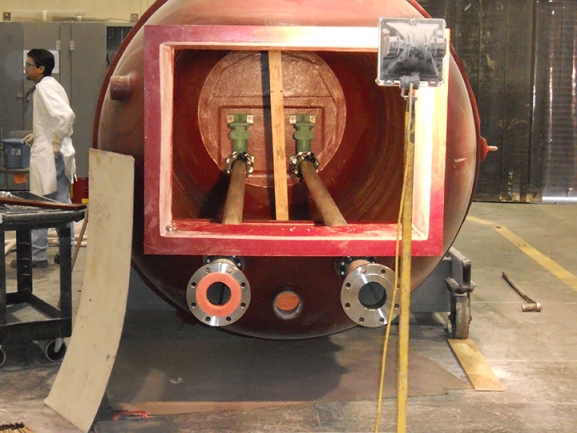

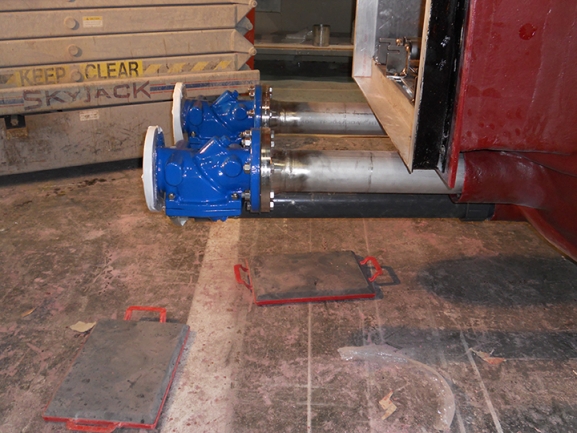

This package wastewater lift station replacement was delivered largely preassembled for quick and simple installation by the customer. This procedure provided an expertly designed lift station that would uphold the privacy values of the facility. The fiberglass wet well arrived with mounting hardware, discharge piping, and the valve assembly preinstalled. Only the duplex solids handling pumps needed to be lowered after installation of the sump. An outdoor UL listed control panel was designed with float controls for liquid level-sensing and included an autodialer for communications.

What Romtec Utilities Provided

- Lift Station Design & Engineering

- Package Lift Station Supplier

- Package Lift Station Manufacturer

- On-Site Lift Station Construction Adviser

- On-Site Start-Up Management

| 350 | 90′ |

| GPM | TDH |

Why They Chose Romtec Utilities

The advantages of a package lift station are especially useful to some customers. This was the case when Dow Chemical Company needed to replace an existing wastewater lift station. Dow Chemical employed staff at its facility capable of excavation and underground installation. It also possessed engineering staff capable of reviewing design documents. What Dow Chemical needed was Romtec Utilities to design, manufacture, and supply a site-specific package lift station that could be reviewed and installed by its existing staff. Romtec Utilities established clear designs for the lift station requirements and then executed an assembly and delivery plan that accomplished Dow Chemical’s preferences for installation.