Romtec Utilities engineers pumping systems for all types of applications, including booster pump stations that maintain water supply pressure.

How to Achieve Multiple Pumping Discharge Rates

Romtec Utilities engineers pumping systems for all types of applications, including booster pump stations that maintain water supply pressure.

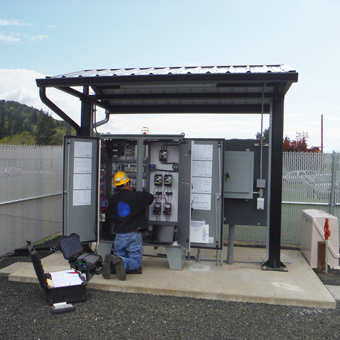

Remote Monitoring

Romtec Utilities engineers pumping systems for all types of applications, including booster pump stations that maintain water supply pressure.

Romtec Utilities Process

Romtec Utilities engineers pumping systems for all types of applications, including booster pump stations that maintain water supply pressure.

Pump Station Heat Tracing with Romtec Utilities

Heat tracing is the practice of applying a heating line and insulation to piping. This is done in very cold climates where there is a possibility of the pipes becoming frozen. Romtec Utilities recently applied heat tracing to the piping and valves in eight vault structures on both stormwater and wastewater lift stations installed at the Union Pacific Railroad (UPRR) in Cheyenne, Wyoming.