Radar level sensors do have a high cost, but they are extremely versatile and are suitable for many difficult operating conditions.

Level Sensor Technologies Pt. 2 – Ultrasonic Transducers

Today we’ll be covering ultrasonic transducers, a reliable level sensing method that uses acoustic signals to determine levels inside the wet well.

Level Sensor Technologies Pt. 1 – Mechanical Floats

Level sensors are components that are included in nearly every pump station, and they are integral to the operation of the pumping system. There are many different level sensor technologies available, each with their own strengths, weaknesses, and ideal water conditions.

Mounting Level Sensors for Pump and Lift Stations

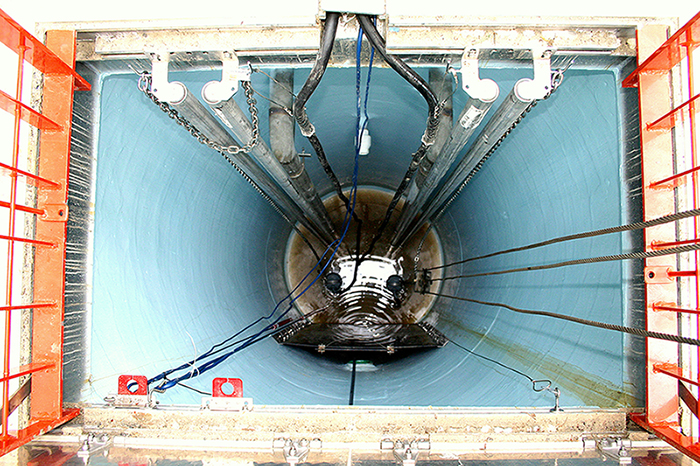

Romtec Utilities fabricates several custom components to correctly mount level sensing devices in pump and lift stations. Level sensors are important devices for the long-term functionality of pumping systems for wastewater, stormwater, clean water, and industrial process water applications. Level sensors trigger the pump of the system to start and stop, and a level sensing failure can lead to a system failure. Romtec Utilities always includes redundant level sensing, but in addition to redundancy, Romtec Utilities has developed a number of mounting options for different level sensing technologies to ensure the continual functionality of these devices. Here are some of the options that we manufacture.

Marathon Petroleum|Robinson, IL|75 GPM - 125' TDH

The Marathon Petroleum Refinery in Robinson, IL needed this new industrial process water pump station to handle its medium flows of highly acidic water combined with standard wastewater. A precast concrete sump included an interior Tnemec coating to withstand the water chemistry from a refinery testing lab. 11 hp Goulds grinder pumps were designed in a duplex configuration and included a factory epoxy coating to withstand the water chemistry. The pump station piping was designed with stainless steel components, and corrosion resistant floats were included as the liquid level sensing devices.