Designing a functional wastewater lift station can sometimes include unique design challenges, and one fairly common example of a design challenge is integrating mixing and/or water agitation to the pumping system.

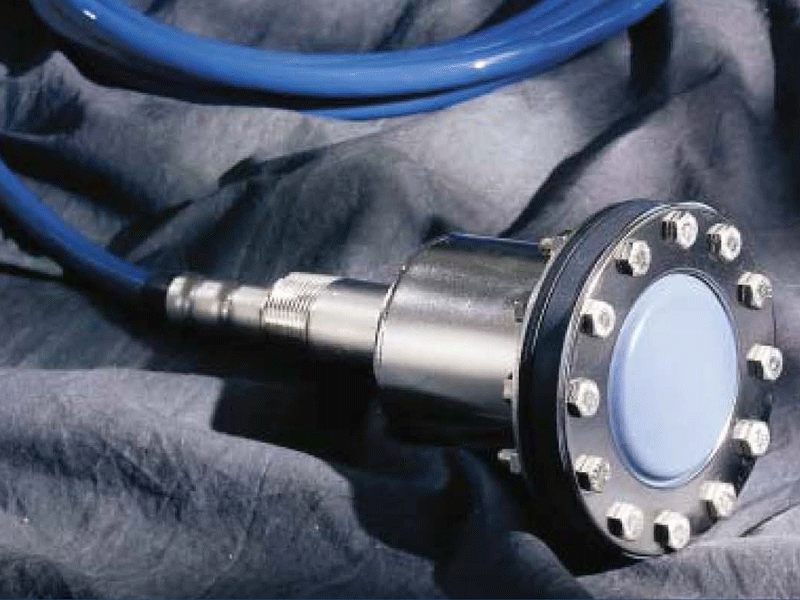

Pressure Transducers for Pump & Lift Stations

Pressure transducers provide pump stations a number of benefits for pump station owners, especially for wastewater. Here is a more detailed look at how these devices work.

The Importance of Redundancy in Pump Station Engineering

For pump stations, lift stations, and booster pump stations, redundancy is an important aspect of the design and long-term functionality of the system. Redundancy in pumping systems can be found in many forms and describes backup systems that can relieve the primary systems in the event of a failure. Redundancy can be required or elective depending on the type of water being pumped and the code requirements of the pump station site. Designing pumping systems with some level of redundancy can be a very important feature of a fully functional pumping system.

Advantages of PLC Panels with Touchscreen HMIs

In lift station controls, HMI stands for “Human Machine Interface” and describes the technology used for an operator to interact with the mechanical and electrical aspects of a lift station system. Romtec Utilities believes that one of the best practices for panel design is to apply a quality HMI on a reliable and flexible programmable logic controller (PLC) platform. Configuring the control panel with an HMI and PLC will give lift station operators access to the full potential of the lift station controller.

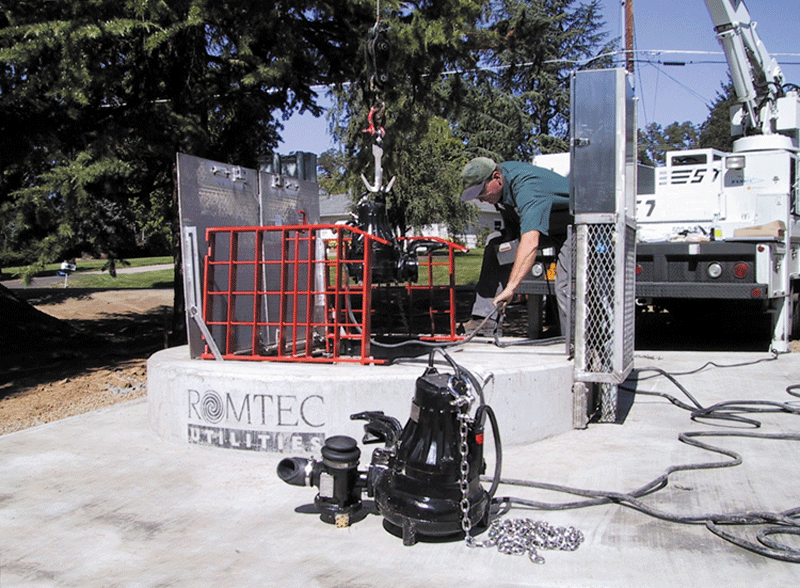

Burbank Housing|Sebastopol, CA|36 GPM - 26.8' TDH

This wastewater lift station was required to hand medium sewage flows from a development neighborhood by Smith River Rancheria, the governing body of the Tolowa Dee-ni’ Tribe. Two Goulds Water Technology 2 hp grinder pumps were used to meet the high head requirements for over 3,000 ft of force main. A owner-supplied control building contains the control panel and an permanent onsite Cummins generator for backup power. A Mercoid pressure transducer provides primary level-sensing controls with Dwyer floats for backup.