Port of Portland – Industrial Wastewater Package Pump Station

Wastewater Lift Station Project Description

The Portland International Airport (PDX) has a new project called PDX Next which expands the terminal from 20 to 35 million passengers per year.

The project will take about five years total and includes a timber roof, a new main terminal, upgrading concourse B, a variety of new Portland food vendors and ground transportation upgrades.

The Port of Portland hired Hoffman Construction and Skanska USA as a joint venture general contractor to deliver the project as a design-build to create the best value, relying on the experience of both companies. HNTB is the architecture firm also working on the PDX Next project.

Coffman Excavation brought Romtec Utilities into the project due to our past experience working on pump systems with the Port of Portland.

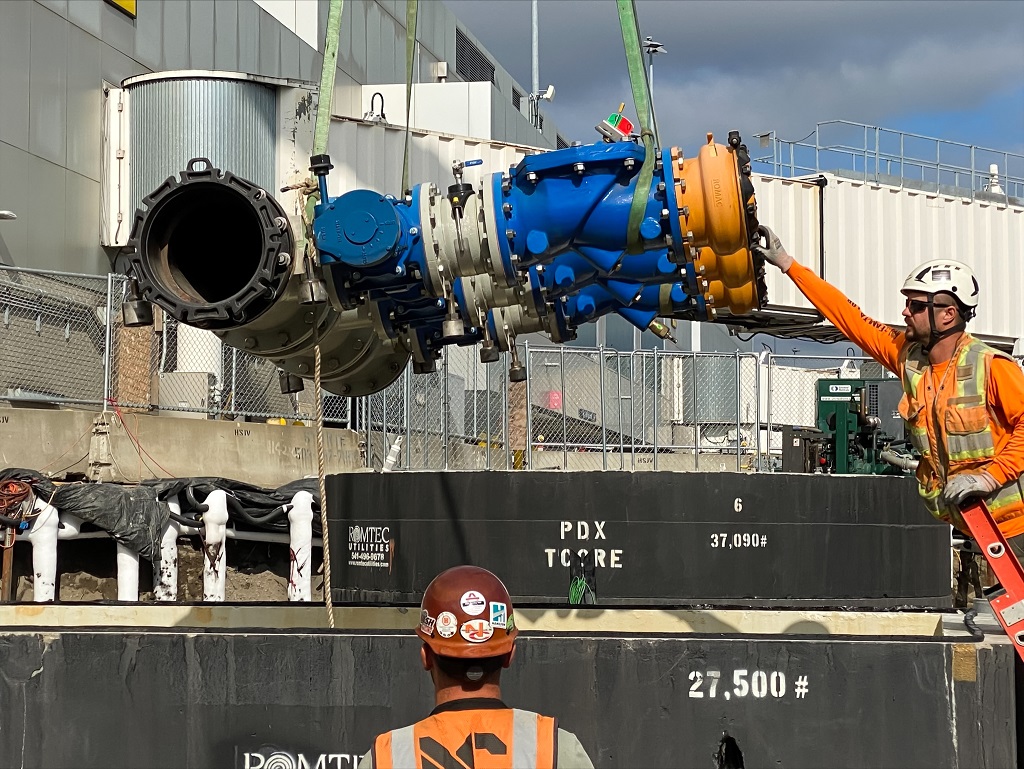

Romtec Utilities designed and supplied the new sewer interceptor lift station which doubles the peak flow capacity of the old lift station. This airport expansion that will double the size of the current ticketing and lobby area when it opens in 2025.

The PDX TCORE pump station is the fifth project RU has done for the Port of Portland in the last five years. The station is the main wastewater pump station for all of PDX.

Package Pump Station Design

The pump station includes two custom in-line grinders, three junction boxes and a 35’ wet well. Coffman Excavation was the installing contractor of the pump station on behalf of the Port of Portland.

The in-line grinders or “muffin monster” is a prefabricated macerator that wastewater passes through to break down and reduce solids before entering a lift station.

Solids in the wastewater can create costly repairs or damage to a pump station. The muffin monster can help cut down on those problems and help with the longevity of the system.

Junction boxes are a structure that provides safe electrical connections between electrical components, such as pumps, level sensors, and the control panel.

The original design of the wastewater lift station on this project was calling for a cast in place structure. Coffman felt that this project could be done in the same manner as the PACR project and thus reached out for RU to provide a precast option.

RU can deliver the design and supply of a package wastewater pumping station as a part of a larger design-build project or directly with the owner. We have worked directly with general contractors and engineering firms on a variety of projects.

Contact us to help you with your next design-build pump station delivery.

The wastewater lift station features:

– Precast 12′ ID x 34.5′ deep Wet Well

– Precast 814 Valve Vault w/ 10″ Piping

– Triplex Flygt 35hp Submersible Pumps

– Primary Controller: Allen-Bradley Compactlogixs L33R

– Primary Level Sensing: Ultrasonic Transducer

– Secondary Level Sensing: (2) NOLTA Float MS1

– NEMA 3R Stainless Steel Enclosure

– (2) 6′ ID x 25.33′ deep wet well

– All structures have aircraft rated hatches

– (3) Romtec Junction Boxes

What Romtec Utilities Provided

- Pump Station Design & Engineering

- Package Pump Station Supplier

- Package Pump Station Manufacturer

- On-Site Construction Adviser

- On-Site Start-Up Management

| 2500 | 59′ |

| GPM | TDH |